TOOL STEEL

Cold Work Applications

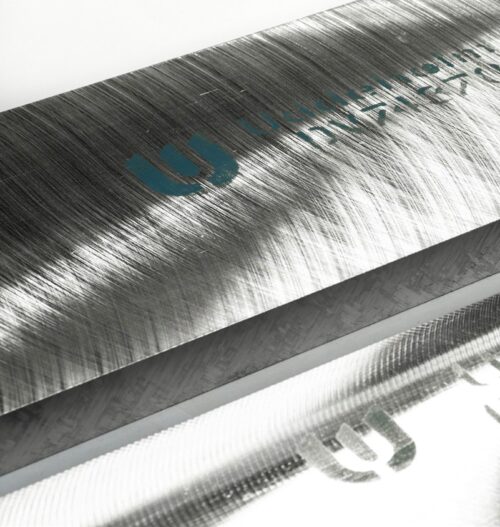

Cold work steel is a special type of steel that is known for its high hardness and wear resistance. Unlike other types of steel, cold work steel is not used at high temperatures, but at room temperature or even at lower temperatures. (up to 250C)

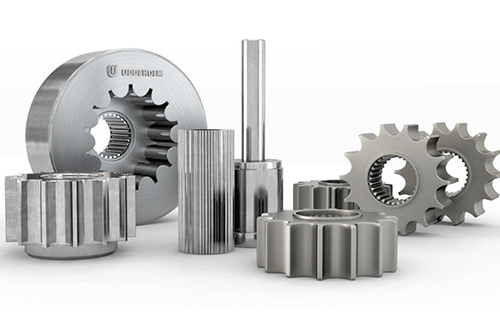

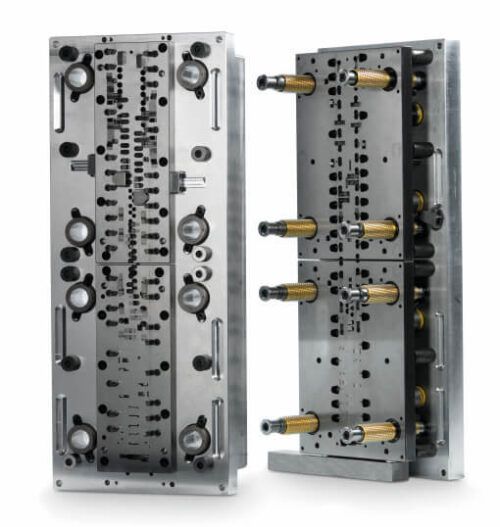

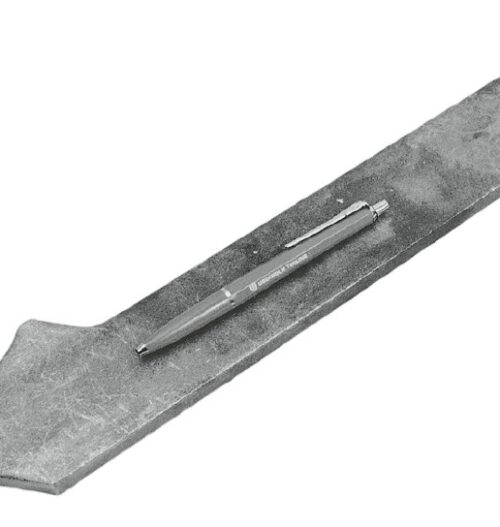

When it comes to cold work, Common failure mechanisms are wearing galling, chipping and cracking. cold work tool steel engineered to counter any failure mechanism that may arise when performing heavy-duty cold work, such as cold forming, blanking and coining.

Cold Work tool steel covers the following:

Uddeholm

Cold Work Tool Steel

Misr Sweden

Uddeholm

Cold Work Tool Steel

Misr Sweden

All Tool Steel For Cold Work Applications

Get Latest Update and News by Following Us on Social Media !

Contact Us at :

Main Office Branch :-

Or Contact Us at :

Abo Rawash Branch :-

Or Contact Us at :

10th of Ramadan Branch :-

© Copyright Misr Sweden. All right reserved