صلب العدة

صلب التشغيل على الساخن

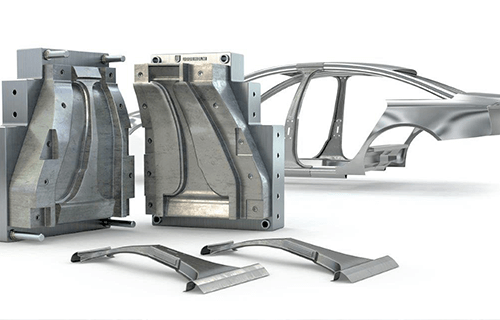

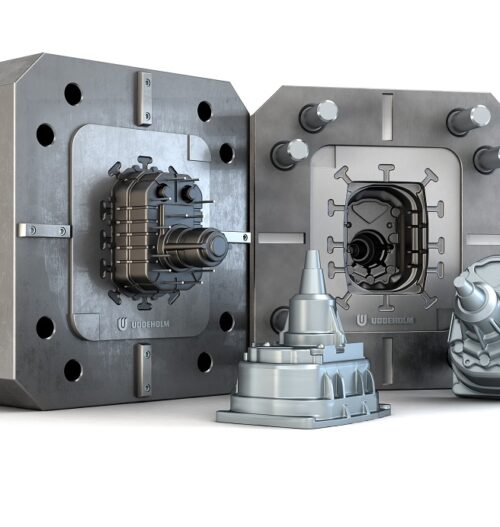

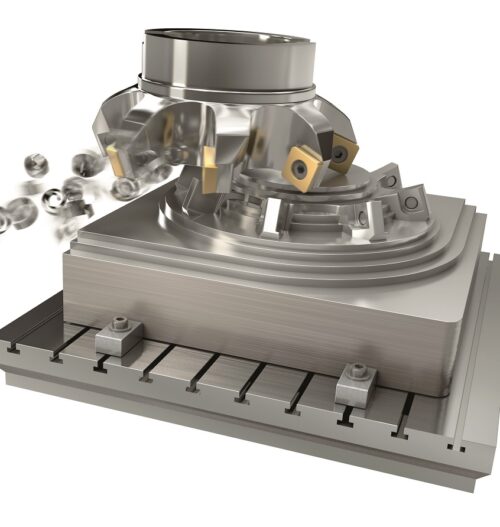

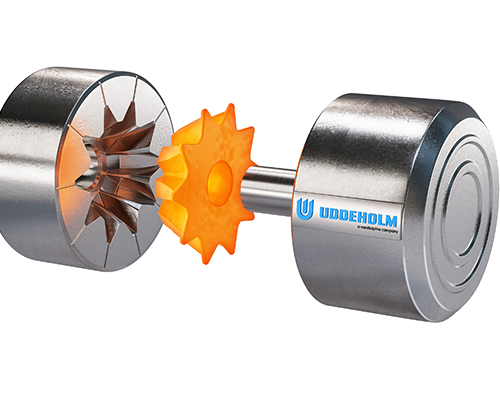

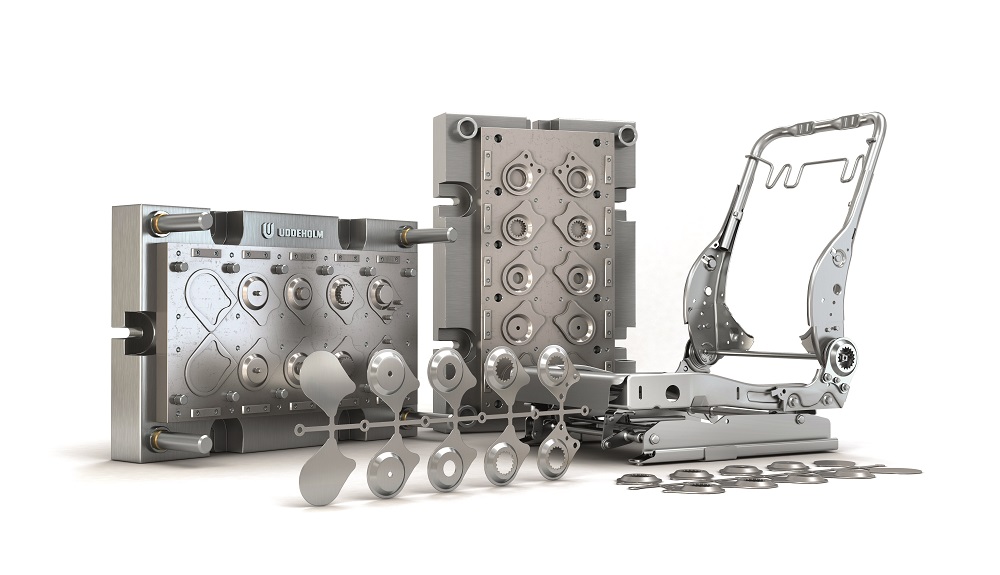

صلب التشغيل على الساخن هو نوع خاص من صلب الأدوات الذي يستخدم بشكل أساسي في درجات الحرارة العالية. يتميز بمقاومة ممتازة للحرارة والصلابة ومقاومة التآكل. غالبًا ما يستخدم صلب التشغيل على الساخن في التطبيقات الصناعية حيث يجب أن تعمل الأدوات والقوالب في ظل ظروف درجات الحرارة العالية.

تعد التطبيقات التي تجدها في التشغيل على الساخن من أكثر التطبيقات تطلبًا في بيئة التصنيع. تساعد شركة مصر السويد العملاء في مجالات التطبيق هذه لسنوات عديدة وهي تغطي ما يلي.

يغطي الفولاذ المستخدم في العمل الساخن ما يلي:

Uddeholm

Hot Work Tool Steel

Misr Sweden

Uddeholm

Hot Work Tool Steel

Misr Sweden

Download Catalogues PDF

All Tool Steel For Hot Work Applications

احصل على آخر التحديثات والأخبار من خلال متابعتنا على وسائل التواصل الاجتماعي!

تواصل معنا

فرع العاشر من رمضان:-

تواصل معنا

فرع أبو رواش:-

تواصل معنا

الإدارة:-

© Copyright Misr Sweden. All right reserved