صلب العدة

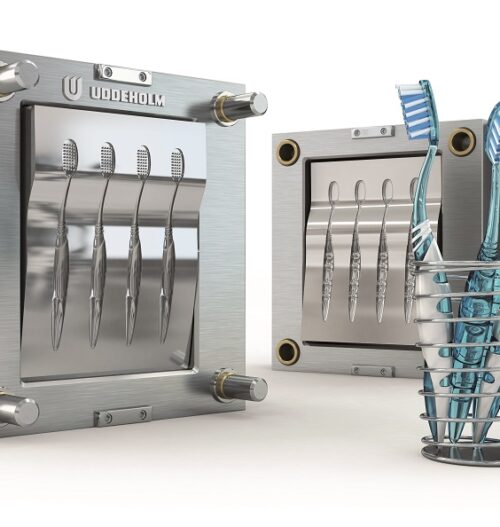

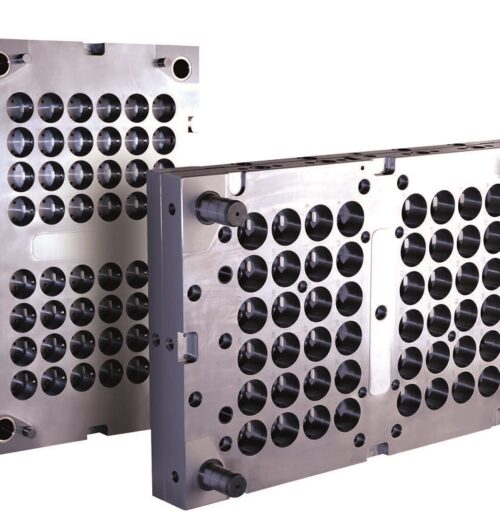

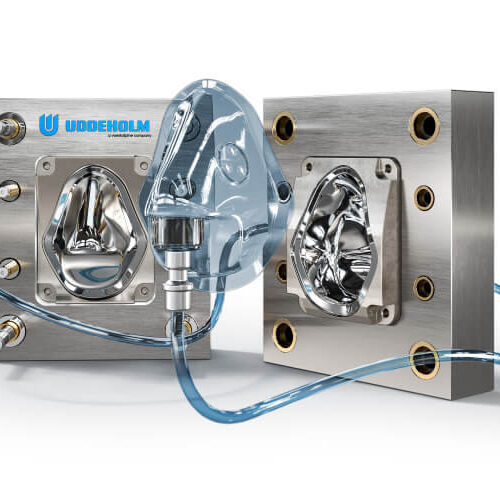

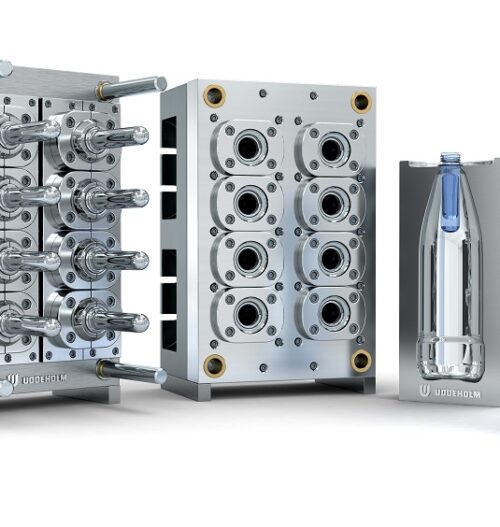

صلب قوالب البلاستيك

صلب قوالب البلاستيك هي صناعة مطلوبة ومتطورة. البيئات القاسية تضع الفولاذ تحت ضغط كبير. إن التآكل ودرجات الحرارة المرتفعة والتغيرات في درجات الحرارة ليست سوى عدد قليل من التحديات الأكثر شيوعًا.

لا غنى عن البلاستيك في عالم اليوم، حيث يخدم مجموعة واسعة من الأغراض. يتم استخدامها في العناصر ذات الإنتاج الضخم مثل التعبئة والتغليف والزجاجات القابلة لإعادة الاستخدام، وكذلك في المنتجات والإكسسوارات عالية الجودة عبر السلع الاستهلاكية والترفيهية والسيارات وصناعات البناء والتشييد. بالإضافة إلى ذلك، يلعب البلاستيك دورًا حاسمًا في قطاعات التكنولوجيا المتقدمة.

يغطي صلب قوالب البلاستيك ما يلي:

Uddeholm

Plastic Molding Tool Steel

Misr Sweden

Uddeholm

Plastic Molding Tool Steel

Misr Sweden

Plastic Molding

احصل على آخر التحديثات والأخبار من خلال متابعتنا على وسائل التواصل الاجتماعي!

تواصل معنا

فرع العاشر من رمضان:-

تواصل معنا

فرع أبو رواش:-

تواصل معنا

الإدارة:-

© Copyright Misr Sweden. All right reserved